What is a Lotion Pump?

The lotion pump is a supporting tool for taking out the contents in the cosmetic container, which is a liquid dispenser that uses the principle of atmospheric balance to pump out the liquid in the bottle by pressing and replenishing the outside atmosphere into the bottle.

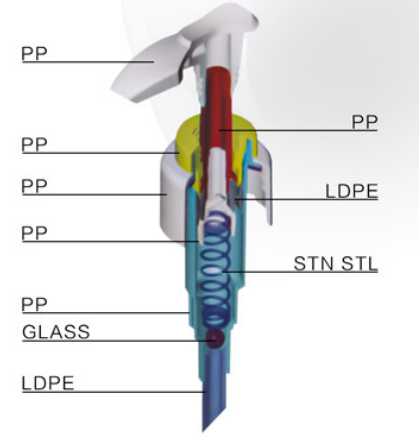

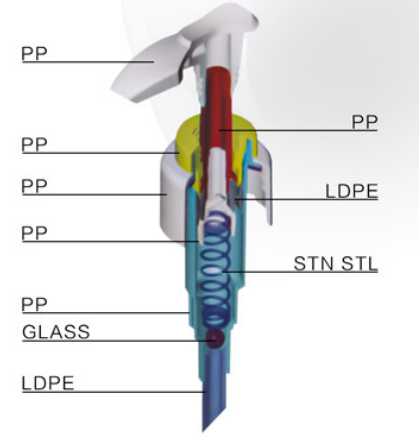

Lotion pump structural components

Generally, the lotion pump is composed of pressing head or called actuator, the upper pump column/Stem, the lock cap/clip, the chaplet, the gasket, the closure, the pump plug, the sub-stem, the spring, the pump body/housing, the glass ball, the straw/diptube and other accessories. According to the structural design requirements of different pumps, the relevant accessories will be different, but the principle is the same as the ultimate goal, that is, to effectively remove the contents.

The production process of the lotion pump

Most of the accessories of the pump head are mainly made of plastic materials such as PE, PP, LDPE, etc., and are molded by injection molding. Among them, glass beads, springs, gaskets and other accessories are generally purchased out. The main components of the pump head can be suitable for electroplating, electrochemical aluminum cover, spraying, injection color, etc. The surface of the pump head and the surface of the braces can be printed graphically, and can be processed by printing processes such as hot stamping/silver, silk screen printing, and pad printing.

Lotion Pump Classification

Conventional diameters: Ф24, Ф28, Ф38, etc.

According to the lock: threaded lock or screw lock, left-right lock, clip lock, no lock

According to the structure: spring external pump, plastic spring, anti-water ingress emulsion pump, high viscosity pump

According to the pumping method: vacuum flask and straw type

According to the pump output: 0.15/ 0.2cc, 0.5/ 0.7cc, 1.0/2.0cc, 3.5cc, 5.0cc, 10cc and above.

How lotion pump works?

Manually press down the pressure handle, the volume in the spring cavity decreases, the pressure rises, the liquid enters the nozzle cavity through the hole of the valve core, and then sprays the liquid outward through the nozzle, then loosen the pressure handle, the volume in the spring cavity increases, forming negative pressure, the ball opens under the action of negative pressure, the liquid in the bottle enters the spring cavity, then there is a certain liquid stored in the valve body, when the handle is pressed again, the liquid stored in the valve body will rush up, and spray out through the nozzle;

Performance indicators

The main performance indicators of the pump: air pressure times, pump output, downforce, head opening torque, rebound speed, water inlet index, etc.

The difference between built-in spring and external spring

External spring, which does not touch the contents and does not cause the contents to be contaminated by the spring rust.

Lotion Pumps are widely used in the cosmetics industry, and are used in the fields of skin care and toiletries and perfumes, such as shampoo, body soap, body lotion, serum, anti-sunscreen, BB cream, foundation, facial cleanser, hand sanitizer and other product categories.

Unionsprayer provide contract manufacturing services for companies around the world that focus on plastic packaging materials, including the category of lotion pumps, if you have such needs, please do not hesitate to contact us.